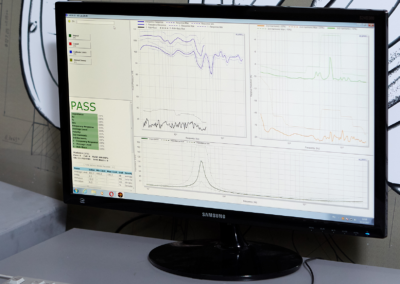

Being on the path of constant technological and engineering innovation, MAG Audio continues to integrate new progressive technologies to control the quality of its products. One of them is Klippel QC, the hardware/software complex for end-of-the-line checking of cone transducers and high-frequency drivers from the leading German manufacturer Klippel.

KLIPPEL is an innovation leader in providing unique test equipment dedicated to electro-acoustical transducers and audio systems. The novel techniques are the result of fundamental research over 30 years that allowed us to obtain more accurate physical models of loudspeakers, micro-speakers, and headphones valid for small and large signal analysis. This research has revealed fundamental distortion causes and provided practical improvement opportunities for transducer design and production. The company was founded in Dresden by Professor Wolfgang Klippel in 1997.

Klippel QC quality control system is designed both for end-of-the-line control on production lines, as well as for checking pilot product batches. Klippel QC can not only reveal defects even in cases, when symptoms are not audible in noisy conditions of real production but also assist with the end goal — to increase the effectiveness of the production line. End-of-the-line parameters check gives valuable information on root failure causes that help to remove the problem as soon as possible.

Ivan Kuzmenko, audio system engineer from MAG Audio, who is responsible for acoustical parameters monitoring, is commenting on the improvement:

The New Klippel QC system is a very important step for us, as it allows us to increase the effectiveness of production lines, while dramatically decreasing the possibility of failures during exploitation.

Vast measuring possibilities of Klippel QC Kuzmenko are seen not only as quality control equipment but as a tool for constant improvement for manufactured products:

Klippel QC allows us to measure fundamental parameters: frequency response, impedance response, and Thiele-Small parameters for every unit produced. Thus, it leaves us the invaluable parameter statistics, which we can analyze to improve existing products while designing new ones.

More detailed information on Klippel QC quality control system is available at www.klippel.de.